1. After Receiving Your New Pump

1. Unpack and inspect the pump for shipping damage and to ensure it meets factory specifications.

2. First, add the supplied oil from our factory, filling it to a level above the center line of the oil gauge. A low oil level will prevent the exhaust valve from sealing, affecting vacuum levels. A high oil level may cause oil spraying.

3. Connect the three-phase power cord as specified. For three-phase motors, ensure the motor's rotation direction aligns with the arrow on the pump bracket. For single-phase motors, simply plug the pump directly into a power outlet. Perform a test run before resuming normal operation. The external power supply for the motor requires an overload protection device to prevent motor burnout.

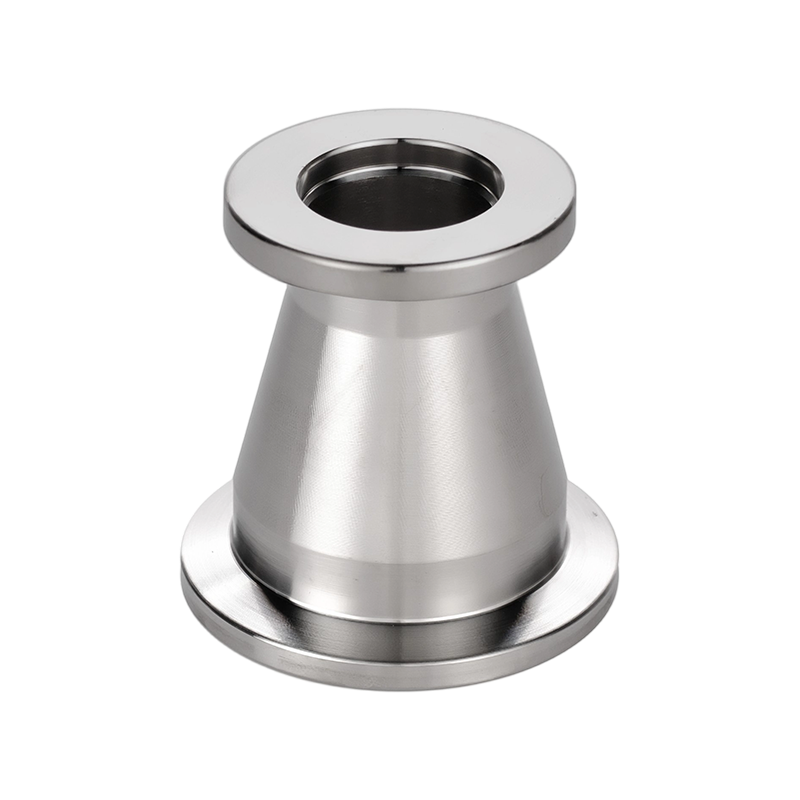

4. The pump's inlet pipe can be connected using a KF connector, straight pipe, or flange. The standard factory-installed connector is a straight pipe. The pipe connecting the pump to the inlet should not be too long. Be extremely careful to ensure that the external connecting pipes, joints, and containers are leak-free and sealed. Failure to do so will affect the ultimate vacuum and the life of the vacuum pump.

5. Pump working environment: Temperature range of 5℃~40℃, relative humidity not more than 85%, inlet pressure 1.3×103 Pa. For vacuum pumps with a pumping speed of more than 0.5L/s, a gas ballast valve is installed. If the relative humidity is high, the gas ballast valve can be opened for purification, which can remove a small amount of water vapor without contaminating the pump oil, extending the service life of the pump oil. After purification, it should be closed in time. This will improve the performance of the pump.

6. Self-priming oil-intake vacuum pumps should be operated at an inlet pressure of 100Kpa~6Kpa for no more than 3 minutes.

7. This pump must be installed in a clean, ventilated and dry place.

8. It cannot be used in any of the following situations:

(1) It cannot pump gases containing particles, dust or colloids, water, liquids and corrosive substances.

(2) It cannot pump gases containing explosive gases or gases with too high oxygen content. For such environments, it is more appropriate to use the explosion-proof vacuum pumps produced by our company.

(3) The system cannot leak and the container that matches the vacuum pump is too large, and it cannot work under long-term vacuuming.

(4) It cannot be used as a gas transmission pump, compression pump, etc.

9. The pump is equipped with a double anti-oil return device, and oil return is not allowed.

10. This pump is a high-precision product and is not a corrosion-resistant vacuum pump. If it is used with gases with components, it is recommended to use a filter.

2. After using for a period of time

1. After the pump has been working for a period of time, the oil needs to be changed. The first oil change can be replaced with new oil after 200 hours of work. The second oil change is generally required after 300 hours of work. The interval between each oil change is 300 hours. The pump oil uses the petrochemical industry mineral oil vacuum pump oil standard number SH0528, and is equipped with HFV-M100, HFV-M200, HFV-A100, HFV-68, SV-68, etc.

2. After changing the new oil, the pump should be allowed to run for 30 minutes under sealing before connecting to the container for work.

3. If the vacuum level drops and then rises after the pump has been operating for a period of time, there are several possible causes: 1. The oil is contaminated, corroded, or emulsified; 2. The seals are aged and need to be replaced; 3. The parts inside the pump body are worn and need to be replaced. See the troubleshooting and troubleshooting table for detailed instructions.

4. Pipe connections and piping must be airtight and leak-proof, otherwise loud noise, oil spraying, and smoke may occur.

English

English 中文簡體

中文簡體